The Hanok and its bioregion

“No building is an island”. How we make buildings is dependent on all the networks, materials and actors of a bioregion. How we make buildings also impacts this bioregion.

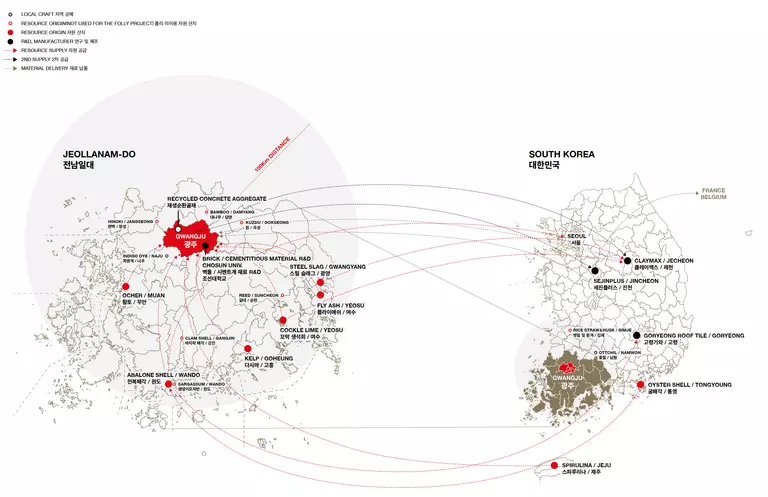

BC materials in a team with BC architects, Assemble and Atelier LUMA was commissioned by the Architectural Biennale of Gwangju, South Korea, to prototype an architectural "folly". The team resided in Korea to research the bioregion and its human networks, focusing on algae farming, bamboo and juniper tree forestry, oyster and cockle supply chains, and vernacular bio- and geo-sourced building systems. Biennale Curator Hyungmin Pai proposed renovating a derelict Hanok building which is a traditional korean housing from 6th century consisting of a bioclimatic design using wood, earth and nature stone as materials.

The setting of the Hanok building within the Dongmyeong-Gong area in the city of Gwangju was chosen to demonstrate bioregional design principles on the crossroads between the urban and the vernacular. Local links, such as with the University of Seoul and Gwangju (Prof. JongWun and Prof. Kim) and the producer Claymax, were strengthened to develop and produce new building materials based on agro-waste, mariculture waste and geo-sourced resources. Thus the EcoHanok emerged from an intensive process - a rich interplay between Korean and European architectural and material practitioners, excellent crafts(wo)men, scientific researchers and innovative industry actors, all focusing on the gifts of the bioregion. For more info on the architectural approach, the BC architects project page can be consulted. Below the different material developments by BC materials, Atelier Luma and different Korean crafts(wo)men are outlined:

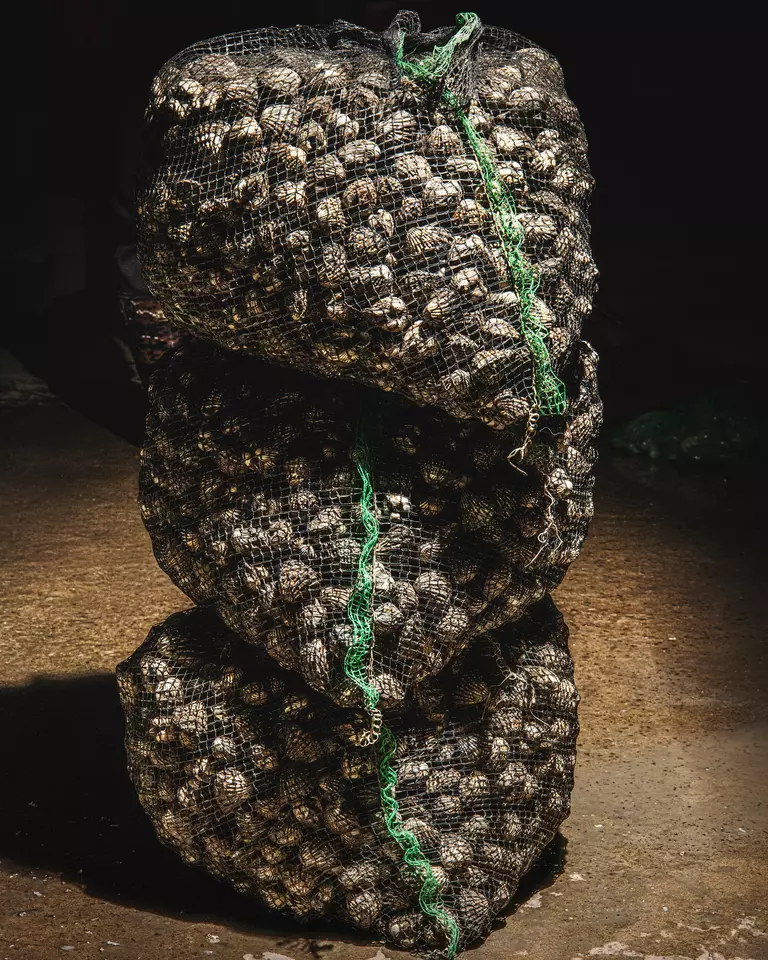

Compressed Oyster Blocks

South Korea's average annual oyster production reaches 150,000 tons, generating approximately six times that weight in shell waste. The compressed oyster block for the EcoHanok is a compressed block made from local mariculture and urban waste around Gwangju, such as crushed oyster shells and cockle lime, as well as crushed concrete from the site. Testing at Chosun University shows an initial compressive strength of 3,4MPa and moderate freeze-thaw resistance. 4000 blocks were produced and used in the exterior garden wall around the EcoHanok.

Plasters

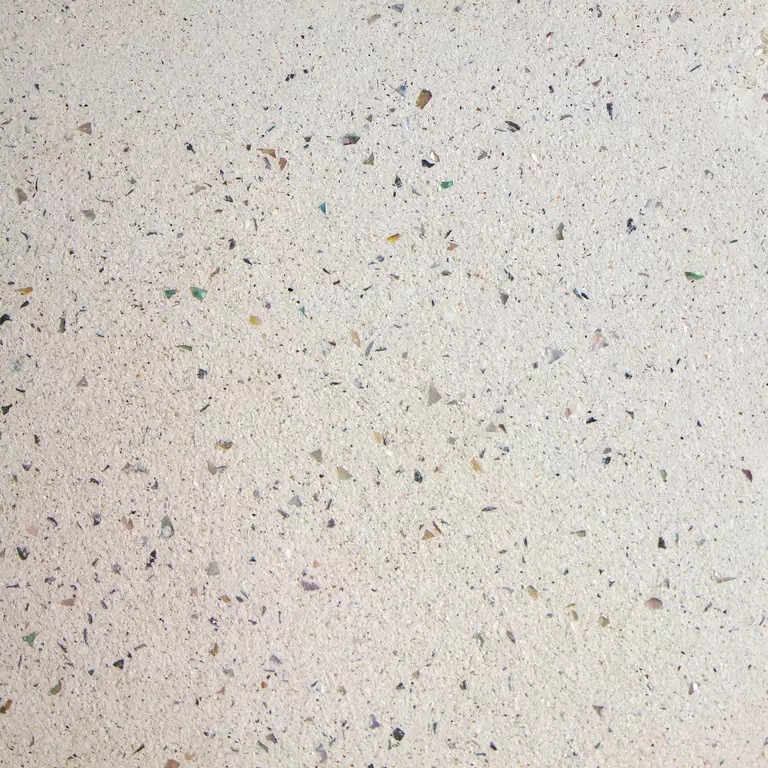

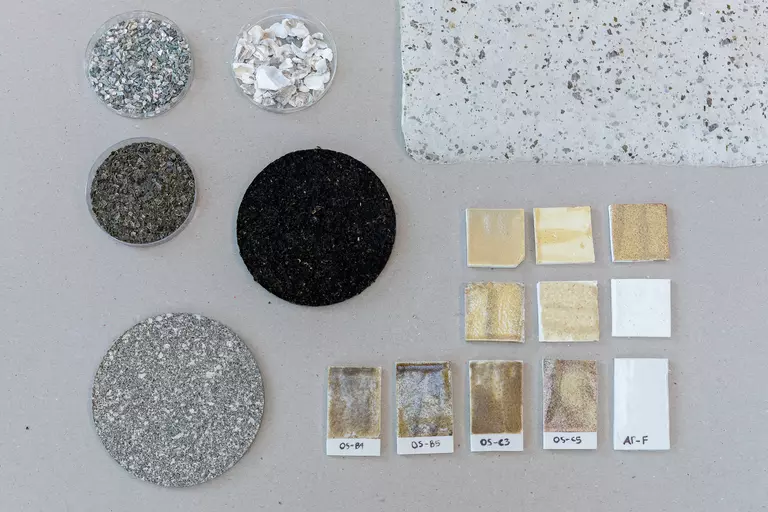

- Oyster and Abalone Plasters:

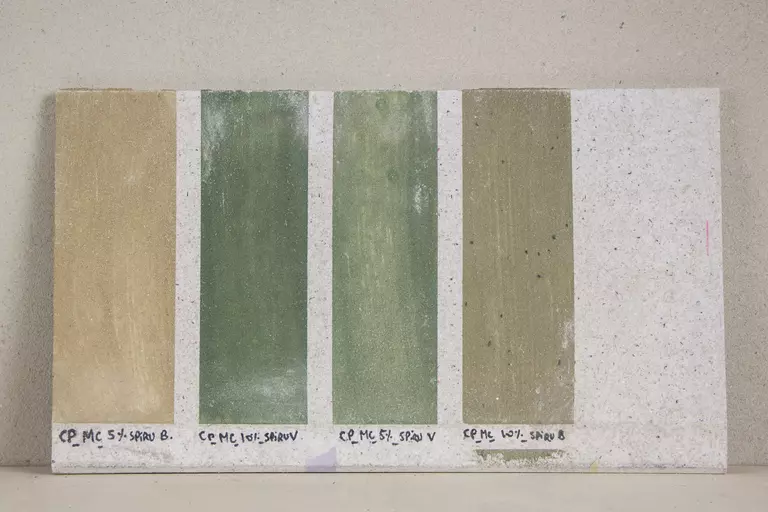

Lime plasters were composed of a binder made from abalone and cockle lime, mixed with crushed oyster shells. These plasters were applied as a textured rendering of the outside walls of the EcoHanok by local craftsmen. - An Algae plaster was composed of the recuperated earth from the construction site mixed with spirulina algae to obtain a colored and cohesive render. It was used as a finish layer in the main room of the EcoHanok.

- An Earth plaster composed of local earth and sand was produced by Claymax and was applied in the kitchen of the EcoHanok. The claymax earth plaster has a red-orange aspect similar to the local earth from the previous construction.

Carbonized rice husk insulation

Those were used for roof and wall insulation as infill in the existing wood and newly added bamboo framework of the EcoHanok. This was especially helpful to fill geometrically irregular area’s framed by vernacular wooden posts and beams.

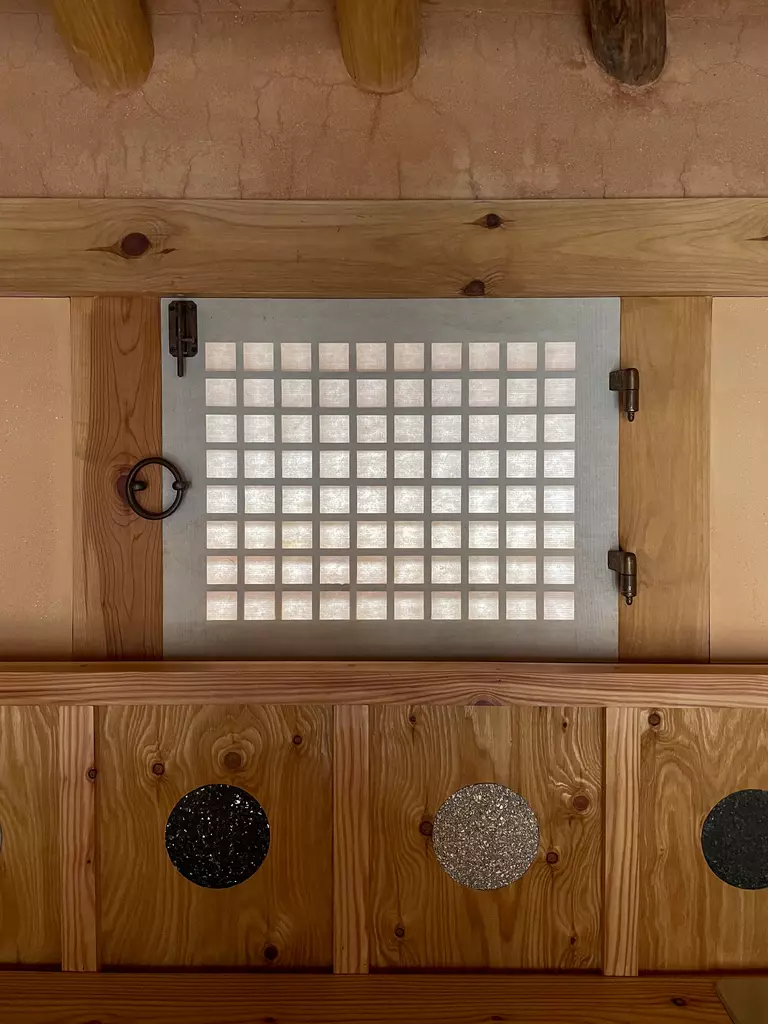

Hanji paper

Hanji paper, a traditional Korean paper made from mulberry trees, is used to cover windows and doors in Hanok houses. For this renovation, we incorporated Kombu seaweed, sea mustard, and spirulina to add color and texture to the paper, used in window and door frames as well as light fixtures.

Indigo carpet

Indigo dyeing is a celebrated Korean craft technique. Two carpets were designed based on oysters and seaweed materials used in the EcoHanok material research. The carpets were dyed by traditional natural dyer Hong Lucca and measure 202x319 cm. The triple-dyed cotton was hand-stitched in a public workshop with 40 citizens of Gwangju.

Glazing of roof tiles

Traditional Korean tiles are blackened through incomplete combustion, while glazed tiles are rare. This research explored glazing traditional roof tiles using powdered abalone or oyster shells. The experimental glaze, developed with Goryeong’s expertise, incorporated iron oxide to create a glossy, bright finish.

Algae panels

Algae panels were created using a heat-pressing process to compact powdered kelp, a waste in Korea’s food mariculture. The panels also incorporated abalone and oyster shell granulates, waste materials in Korea, adding a shiny finish. Some panels were included in the kitchen design of the EcoHanok as part of the furniture.

- Location

- Gwangju South Korea

- Client

- Gwangju Biennale Foundation (Gwangju Folly V)

- Concept

- 2024

- Architects

- BC architects & studies Assemble Atelier LUMA

- Contractor

- Stuga, October Kim Studio, Jangjibang and Studio Ohyukyoung

- Local Executive Architect

- Urban Society

- Material development

- BC materials + Atelier LUMA + Yoon Jungwon (Architecture Production Curator) + Kim Hyeong Ki (Laboratory on Construction and Building Materials of Chosun University)

- Curatorial team Gwangju Folly V

- Pai Hyungmin, Yoon Jungwon, Kang Dongyoung, Lee Youngmi, Cha Jeongwook, Lee Hyewon, Kim Green, Kim Sangho and Serene Pac