Atelier Luma and its bioregion

Atelier Luma (FR) engaged BC materials to research bioregional resources of the Camargue region in order to develop building materials. Mainly sourced from agricultural and quarry waste streams in the region, different resources were collected, studied and developed. In the quarry of Vallabrix large quantities of orange clay slurry became available due to sand washing activities; in the quarry of Sarragan, white debris sand from decades of stone cutting provides for a valuable resource; in the fields of Camargue, sunflower harvest waste provides for strong fibres and light aggregates from sunflower stem and pith; in the recycling centre of Nimes, building demolition waste is sorted and crushed to become gravels.

The resources were wet, mixed, sprayed, compressed, smeared and/or cured in order to discover their potential as a building material. This resulted in both handmade and lab testing. Those deemed to have potential were further developed into full scale validated prototypes in which the executing craftsmen and contractors were involved. The validation happened through different sets of norms (German, French, European, ...) as discussed and chosen by the project team. In the end, 6 building materials were developed and validated by BC materials, by the Control Office Socotec, by the engineering office Betrec and by the team of architects.

Rammed earth, compressed earth blocks and earth mortar made use of mainly Sarragan debris sand and Nimes demolition waste. These materials were used for load bearing internal walls in the project and gave them their characteristic white colour. Contractor Tanzi provided the premix of resources, while Atelier Kara executed the rammed earth works, BriTeCo produced the blocks on site and Pierre au Carré masoned them.

Earth (base layer) plaster was composed of the orange clay slurry from Vallabrix as well as Sarragan's debris sand. It was executed by Het Leemniscaat.

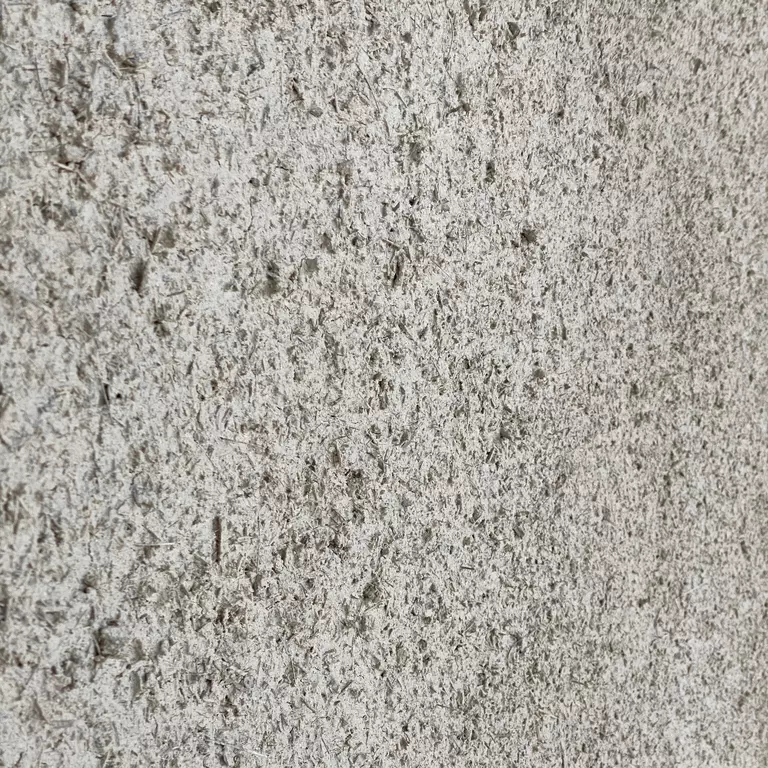

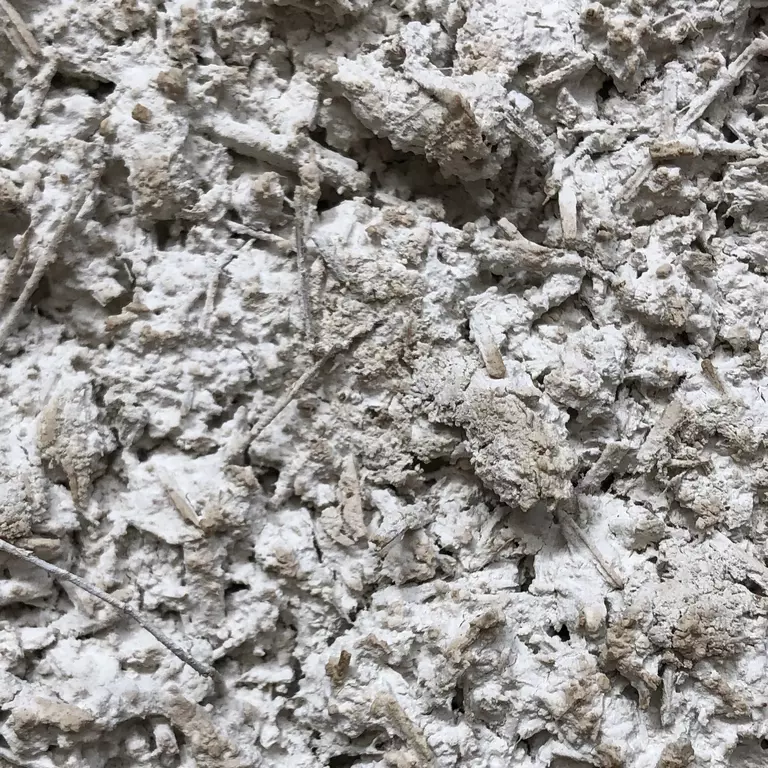

Acoustical earth plaster contained Sarragan's debris sand and more importantly the chopped stem and pith of the Camargue sunflower waste. While the strong stem fibre gives structure, the soft and elastic pith provides for a lightweight aggregate, resulting in a porous and elastic plaster which absorbs sound at the same value as market PUR foam acoustic panels, reaching an α of 0,7 (tested in ENTPE Lyon). The acoustical plaster was executed by Het Leemniscaat.

Algae plaster contains algae processing waste from Sète in combination with a wide range of resources, resulting in a palette of colours. Exceptional results in abrasion resistance, impact strength and adhesion were achieved by mixing the algae with the debris sand, pointing to an interaction between carbonates in the sand and algae polysaccharides. The execution was done by craftsmen Rachid.

- Location

- ArlesFrance

- Client

- Atelier Luma

- Concept

- 2020

- Architects

- BC architects&studies Assemble Studio

- Technic

- Rammed earth, Clay plaster, Compressed earth blocks

- Premix

- Tanzi

- Base & acoustical plaster

- Het Leemniscaat

- CEB masonry

- Pierre au carre

- CEB production

- Briques Technic Concept

- Plaster finishing

- Rachid

- Rammed earth

- Atelier Kara

- Type of act

- Consulting & development / Design & Prefabrication