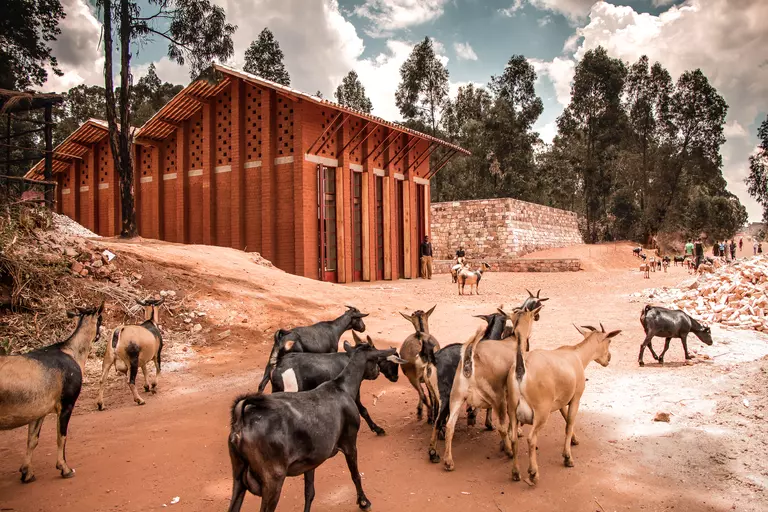

Library of Muyinga

As part of a future inclusive school for deaf children, the first library of Muyinga is a story on how to think and build differently. The cost of most construction projects happening in Burundi is often high, due to overhead costs of international team members, use of imported materials (mainly cement and steel) and the need of highly skilled contractors traveling from the capital Bujumbura or even further, to install special techniques.

The challenge of limited resources for this project became an opportunity. We managed to respect a short supply-chain of building materials and build with local labour force, supporting local economy, and instilling pride in the construction of a library with the people’s material: earth.

A thorough study of vernacular architectural practices in Burundi was the basis of the building's design. Two months of fieldwork in the region and surrounding provinces gave insights into local materials, techniques and building typologies. These findings were applied, updated, reinterpreted and framed within the local know-how and traditions of Muyinga over a 5 year period. Through educational participatory programs many students were able to engage in the construction process, allowing for the continuous cycle of knowledge transfer to happen in parallel to the built project.

Construction; local materials and solutions

- Dry stone walling: systematically stacking of natural stone without the use of mortar for the retaining walls, to enable the water to pass through and lessen the lateral earth pressure on the walls, while cutting down costs by not using cement.

- Compressed Earth Blocks (CEB) masonry: made from a mix of sand and earth from the site, these unbaked bricks provide beautiful and easy masonry with earth mortar jointing.

- Baked clay roof and floor tiles: the roof and floor tiles are fired from locally sourced valley clay.

- Sisal hammock: a hammock woven from the sisal plant found on the construction site, with local weavers extending their knowledge into innovative weaving techniques.

- Earth plaster: the interior is plastered until the ring beam with an earth plaster with unbaked clay from the valley, and sand.

- Eucalyptus wooden beams: the roof structure is made from Eucalyptus beams, processed in cooperation with a local forest manager, which grows and harvests Eucalyptus trees in managed cycles.

Beyond the use of building sustainable through materiality and locality, at the heart of this project sits the learnings of ways to build capacity and transfer knowledge within a community and engaged parties.

- Location

- MuyingaBurundi

- Client

- The diocèse of Muyinga

- Architect

- BC architects & studies

- Contractor

- The community of Muyinga

- Technic

- Compressed earth Bricks and earth plasters

- Type of act

- Consulting & development